The new AlgaTECH algae production facility at the University of Turku uses greenhouse or industrial waste water to produce ecological and cost-effective algal biomass. The researchers are developing new and suitable uses for algae biomass. The aim is to promote the Nordic bio-industry.

The aim of the University of Turku's Molecular Plant Biology research group has been to develop a microalgae production system based on a circular economy, which is particularly suited to the Finnish environmental conditions.

For this purpose, the researchers have established the new AlgaTECH algae production facility at the Ruissalo Botanical Garden. The facility uses nutrient-rich greenhouse wastewater to produce valuable algal biomass.

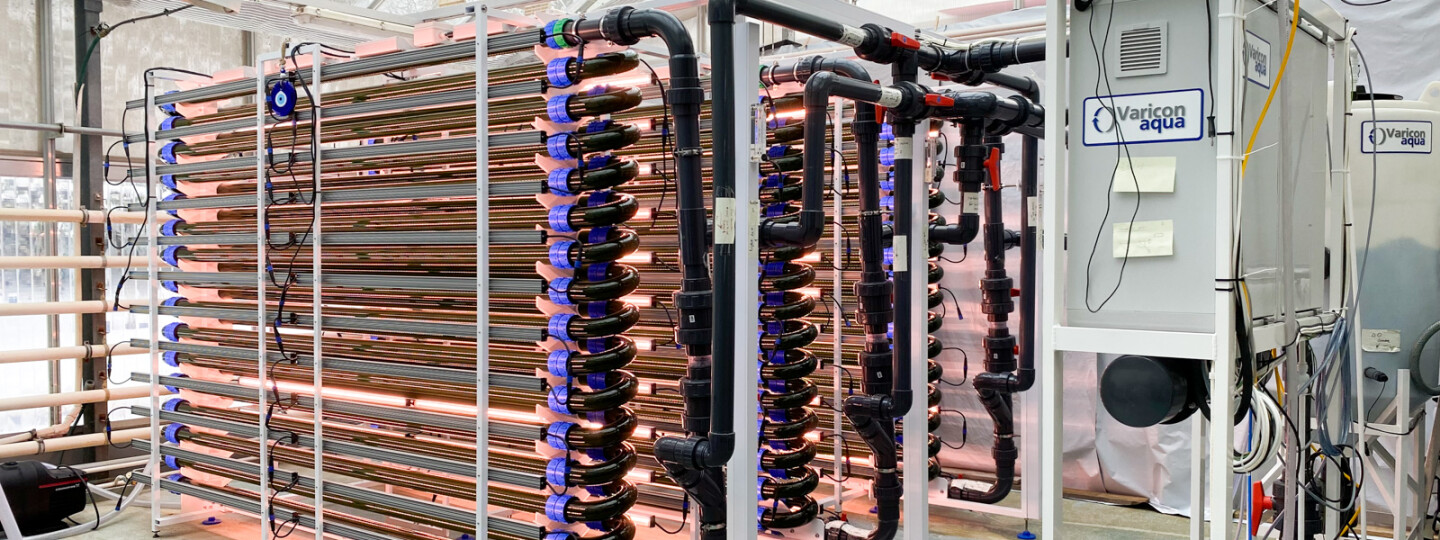

The photobioreactor, which is over a cubic meter in size, is the largest algae research and testing facility in Finland for the biotechnology and bioeconomy sectors.

The construction of the algae production plant is part of the EU-funded REALM (Reusing Effluents from Agriculture to unlock the potential of Microalgae) consortium project, which aims to develop the use of algae in agriculture and support the blue bioeconomy in Europe.

New algae production concept offers great potential for the Finnish biotech industry

The pressing global challenges of climate change place significant demands on the bioeconomy. Algae can grow very rapidly and produce sustainable biomass, which can be used for example for food, feed or as a source of chemicals and fuels. Algae can therefore be classified as a third generation of sustainable biomass.

Elsewhere in Europe, the algae-based industry has been growing rapidly, but in Finland the development of the algae sector has been slow, due to the challenges of growing algae in the cold and dark northern climate. Production costs have been high, which has been a major bottleneck in the commercialisation of algae biomass-based applications.

Now, the research group has developed a circular bioeconomy concept for algae production in the Finnish environment, where microalgae can be cultivated in an ecological and cost-efficient way. The algae production uses microalgae from the Baltic Sea and Finnish lakes.

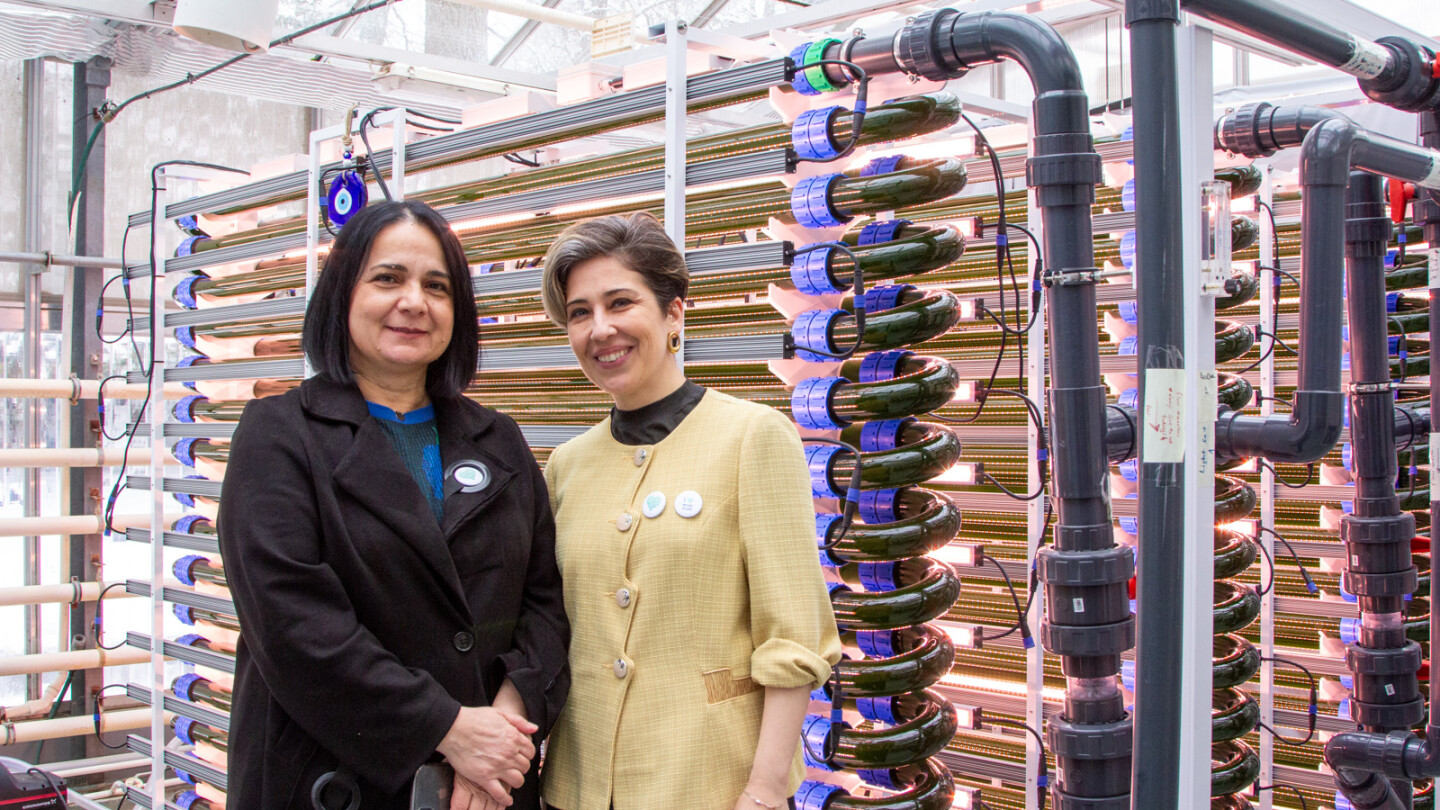

"The photobioreactor uses nutrient-rich wastewater from agricultural and industrial side streams to grow algae. The biomass can be used in a variety of ways in the bioeconomy. In our research we are currently exploring potential applications for different algae species, for example as innovative plant bio-stimulants, or biopesticides for agriculture and food and feed applications. We have accumulated a large amount of knowledge through the research in the lab, and now it is time to demonstrate its potential on a larger scale in a greenhouse environment. With such large-scale facility we are aiming bridging the gap between science and industry, " says professor Yagut Allahverdiyeva-Rinne, the leader of the research group.

Photobioreactor produces valuable biomass and purifies waste water

To grow, algae need light, water and carbon dioxide. They also need nutrients, nitrogen and phosphorus, which are abundant in waste water.

The new photobioreactor has been integrated into the existing greenhouse infrastructure at the Botanic Garden. In the first stage, the wastewater from the greenhouse is pre-treated to remove the pollutants, leaving behind the nutrients needed by the algae. Water and carbon dioxide-rich air are then fed into the bioreactor's algae cultivation pipes, which are illuminated by adjustable LED tubes in addition to natural light.

In the surrounding steady warmth of the greenhouse, algae grow quickly. The reactor has a maximum capacity of 1000 liters and grown biomass can be harvested from the tubes daily. From the growth tubes water is fed into a device that separates the algae mass from the clean water. With the cycle, hundreds of liters of new effluent can be fed into the reactor every day.

The end product is a concentrated and dry algae biomass that can be used in the processing of various algae-based products. The research team is currently investigating the use of different algae species, for example as biostimulants and plant nutrients.

“The new large reactor serves as a validation facility to ensure the most optimal production methods for potential products for industry. Prior to this, we have already tested the process in smaller pilot reactors. For example, we are investigating the effect of different algae species, nutrient levels in the wastewater, lighting or cultivation time on the properties of the final algae product and on the efficiency of the cultivation process," says senior research fellow Sema Sirin.

In addition to the algae biomass, the separation process produces purified water.

“Greenhouse producers, for example, need to treat their wastewater, and this method is a very viable option. After algae cultivation, the separated water is either clean or, if there are nutrients left, it can be returned to the reactor’s cycle, so no waste will be left in the process," says Sirin.

The current facility is of a size suitable for research and testing purposes. For example, a daily collection of 200 litres can yield 200-300 g of finished algae mass. The capacity can be increased by increasing the volume of the reactor.

Towards sustainable biotechnology and knowledge-based education

"Building a photobioreactor is actually quite common. What is really important is that within this facility we are able to leverage our deep expertise in photosynthesis and biotechnology. We're not limiting ourselves to biomass-based technologies. Our aim is to use AlgaTech to scale up novel biotechnological processes, including the production of solar chemicals, fuels and food from engineered microorganisms. To achieve this, we have recently secured over €2.2 million from the Erkko Foundation," says Allahverdiyeva-Rinne.

The research group will also test a Direct Air Capture (DAC) unit in the greenhouse. This unit, provided by collaborators at the University of Twente, will capture CO2 from the air, concentrate it and feed it to algae cultures.

"Given that 1 kg of algae can capture 1.8 kg of CO2, this concept makes a significant contribution to CO2 capture and utilisation," says Allahverdiyeva-Rinne.

The AlgaTech facility is also important for the training of future professionals in the Faculty of Technology's Master's programme in Sustainable Biotechnological Processes.

“The facility will play a pivotal role in enabling us to attract talented students and educate experts in biotechnology and the blue bioeconomy, “Allahverdiyeva-Rinne says.

The research team is developing algae production in collaboration with leading European algae companies. The AlgaTECH research is funded by the EU Innovation Action Project REALM (Reusing Effluents from Agriculture to unLock the potential of Microalgae), part of the Horizon Europe Programme. The project is also supported by a donation from the Maa- ja vesitekniikan tuki ry.