Where top-level research is conducted, the patients also receive first-rate care. Patients’ interest is also based on this same logic when they are selecting a hospital. In the joint orthopaedic research unit of the University of Turku and Turku University Hospital, new and improved methods are developed, which in turn benefits the patients of Tyks Orto – a top-level medical clinic focusing on injuries and diseases of the body's musculoskeletal system. The latest research results from this spring are interesting also to implant manufacturers all over the world.

– Benefit for the patients’ health is the goal in all our work. The benefit has to be proven, and the work adjusted so that the treatment is as good as possible, states Ville Äärimaa, Docent at the University of Turku, Chief Physician at Tyks Orto, and the Head of the Operational Division of Diseases of the Musculoskeletal System at Turku University Hospital (Tyks).

The Operational Division of Diseases of the Musculoskeletal System has an enormous volume. Patient numbers are great and there are 8,000 surgeries each year, 2,500 of which are arthroplasties. In addition, there are approximately 60,000 patient visits.

When the experts develop the effectiveness of the treatments, each patient is of a special interest. The patients are requested to respond to a disease-specific quality of life survey before and after the treatments. The survey on the impact of the disease on daily activities makes it possible to separate data on a municipality level as well as to monitor how well the care of arthroplasty patients is progressing in real time.

– We have great expertise and a versatile group of experienced orthopaedic specialists. We are also constantly training the next generation. Our research is of a very high quality and almost everyone at the clinic is involved in it. When we constantly monitor, report and discuss our processes openly, we can keep our standards high, says Äärimaa.

He also highlights that the waiting period for treatment, which is highly important to the patient, is on a very good level at Tyks Orto. When the patient comes for a visit with a referral, they are usually given the date for the operation on the same visit.

Patient’s Benefit Is the Key

In arthroplasty, the benefit to the patient is the key. The benefit has to be guaranteed, i.e. doctors have to be able to reproduce it in many patients. Timing is also a critical aspect in surgery. If the surgery is performed on the basis of minor or slight symptoms, the artificial joint might not feel comfortable. But when the surgery is performed at the right time, the patients are extremely happy.

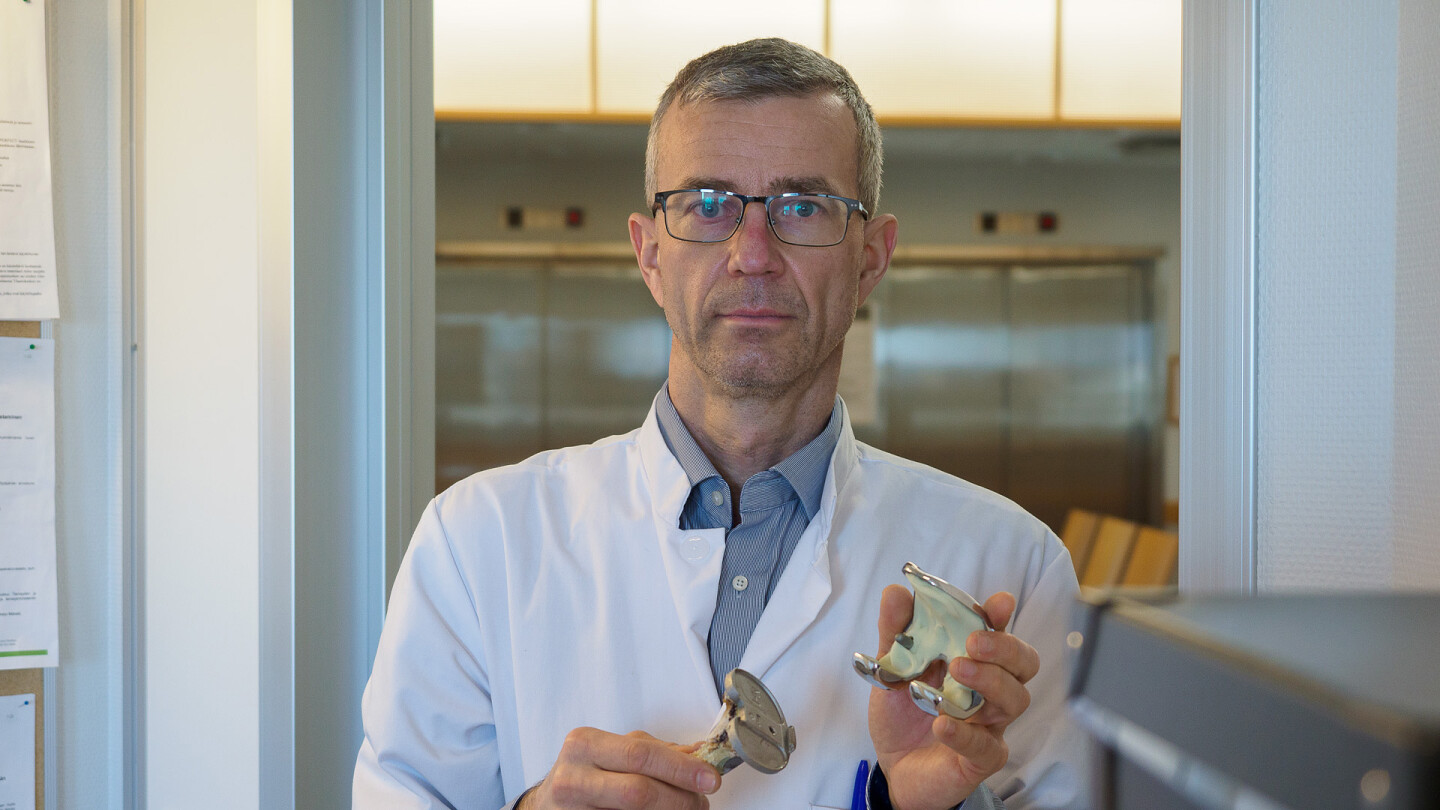

– I have been an orthopaedic surgeon for 20 years. It is my own clinical forte and, at the same time, I’m working as a professor at the University of Turku. The strength of Tyks Orto is applying research results into treatment practices, says Keijo Mäkelä, who is the acting Professor of Orthopaedics and Traumatology at the University of Turku as well as the head of the research unit at the Tyks Operational Division of Diseases of the Musculoskeletal System.

The joint research unit of the University of Turku and Turku University Hospital constantly develops new and improved treatment methods. A good example are the unit’s studies on biomaterials: bioactive glass could be a useful material for bone implants in the future. The researchers are also interested in improving arthroplasty with new technology and 3D-printed implants, studying the role of stem cells in bone healing, and PET imaging of infected implants.

On-going and comparative clinical study is significant for patient care at Tyks Orto. Mäkelä’s area of expertise is quality registers.

– We know how we can succeed with arthroplasty and what we can achieve with register data.

For example, one discovery that has emerged from the registers is the so-called Nordic paradox: at the same time when the use of new titanium implants became more common, the need for revision surgery suddenly increased. Therefore, practices were changed on the basis of register data. Now, the implants are used on the right patients.

– The first few weeks with titanium implants integrated through bone growth are critical. We have to place the components so that they do not migrate after the surgery. When the ossification occurs, the titanium-bone integration is usually so durable that it can last for decades. Therefore, the beginning is the most crucial, says Mäkelä.

Mäkelä is the chair of the Finnish Arthroplasty Register. He was also the chair of the Nordic Arthroplasty Register Association during 2014–2020.

Significant Results among Female Patients

Professor Emeritus in Orthopaedics and Traumatology Hannu Aro is extremely excited. The results of the longitudinal, unique follow-up study led by Professor Aro have just been published in the leading US journal, Journal of Bone and Joint Surgery. The research partners included the Academy of Finland and international implant and pharmaceutical companies.

– The study was targeted on a very important patient group. We studied how hip replacement surgery succeeds in 60–75 year-old women past their menopause, who are the largest group in arthroplasty. In a way, this is a fantastic study, we are the only research unit in the entire world focusing on this subject, Aro highlights.

– It is a question of how the quality of the bone impacts healing. Our study is a follow-up on what happens in arthroplasty if the patient has a cementless implant after menopause.

This is significant because, after menopause, women’s bones weaken quickly. The women were studied in three separate research sets, and it was followed how well a cementless implant stays put, is attached, and remains in place in a more brittle bone. The results show that if the bone is softer, small movement called migration can occur after the surgery when the implant is attaching to the bone. It was a surprise that in many patients the low bone density was not observed in regular bone density tests. The situation was only revealed when a CT scan was applied in studying the bones.

– The research results are so significant that even British and American companies are interested in how we will move forward. The treatment does not only include inserting an artificial joint, but also the question of whether we should treat the bone at the same time. New medical molecules are being developed for this purpose, says Aro.

It is typical in arthroplasty that people start walking immediately after the surgery and that full weight is placed on the foot. When the bone is brittle, the stem of the prosthesis will not stay in the position it was placed in. However, the amount of twisting and movement is very small and detecting it requires a radiostereometric analysis.

Nevertheless, the latest analysis tells us that this migration also affects patient’s recovery and the difference can be observed especially in spontaneous walking speed. In a five-year follow-up, all the patients who had undergone a surgery had recovered, but the experience of the first few months can reflect long into the subjective experience on the results of the surgery.

– The results are very significant and will affect our treatments.

– A hip replacement surgery must be done once and only once. A revision surgery can never be the equivalent of a successful first arthroplasty. This is why our research is so important, Aro emphasises.

Turku University Hospital, the Faculty of Medicine at the University of Turku, and the surrounding campus area form a multidisciplinary cluster of excellence in which research and the high-quality treatment based on it form a seamless entity. More than one thousand scientific studies are under way in these organisations, engaging approximately 1,500 experts. Approximately 200,000 patients receive treatment at Tyks every year. Visits to outpatient care total over 1.2 million and days at inpatient care almost 300,000. The University of Turku and the Hospital District of Southwest Finland are part of the Health Campus Turku network, which also includes Åbo Akademi University, Turku University of Applied Sciences, Novia University of Applied Sciences and Turku Science Park Oy.

Text: Sini Silvàn

Photos: Mikael Soininen

Translation: Mari Ratia