Master's Degree Programme in Mechanical Engineering: Digital Manufacturing

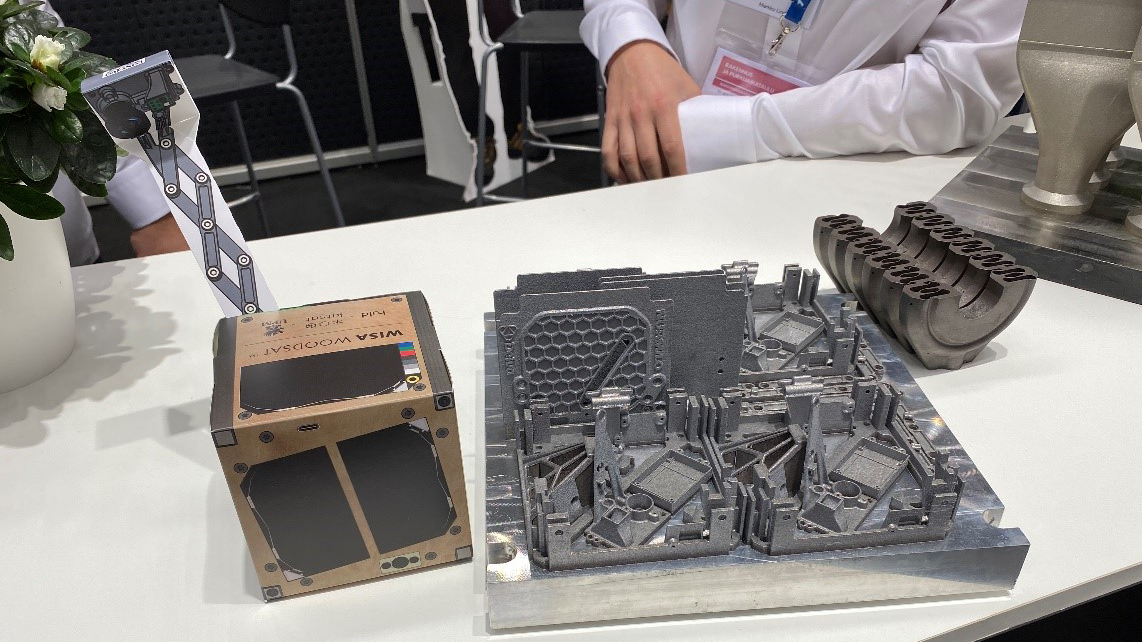

In the Digital Manufacturing track, you will learn skills that will enable you to develop innovative solutions for digital manufacturing technologies utilized in a wide variety of applications and in various industries. In fact, you will also learn the skills to design and manufacture your own 3D-printers along with designing and printing various materials (metals, ceramics, polymers and their composites) for various applications.

Think 3D Print 3D with Digital Manufacturing track!

The Digital Manufacturing track trains fresh graduates as well as experienced engineering professionals with thorough theoretical understanding and hands-on practical skills in 3D printing and other digital manufacturing technologies along with various traditional manufacturing technologies.

Digital manufacturing (including also 3D printing or Additive Manufacturing (AM)) is considered as one of the key pillars in creating a sustainable and digital industrial era through the ongoing industrial revolution, Industry 4.0 along with Big Data and the Internet of Things. Digital manufacturing is a key enabler of the transition from industry 4.0 to industry 5.0 which foster harmonious and synergistic collaboration between humans and machines with enhanced focus on sustainability and environment.

Industries around the globe are thriving for maturing various digital manufacturing technologies and are facing a serious deficiency of skilled engineers trained in such a highly demanding field. Therefore, this master-level programme is custom-designed to educate and train young ambitious graduates as well as experienced engineering professionals to be the next digital manufacturing experts who can solve the challenges that various industries are currently facing.

Digital Manufacturing is one of the three specialisation tracks of the Master's Degree Programme in Mechanical Engineering. The other specialisation tracks are

Entry requirements

General Requirement

You are an eligible applicant for Master’s-level studies if

- you have a nationally recognized first cycle degree – normally a Bachelor’s degree – from an accredited institution of higher education,

- your degree corresponds to at least 180 ECTS (European credits) or to three years of full-time study,

- your degree is in a relevant field for the Master’s degree programme that you’re applying to. Please check the section on track-specific admission requirements for detailed degree requirements.

Language Requirements

Applicants must have excellent English language skills and a certificate that proves those skills. You can indicate your language skills by taking one of the internationally recognized English language tests.

Applicants must reach the minimum required test results to be considered eligible to the University of Turku. No exceptions will be made. Read more about the language requirements here.

Study right

It is not possible to have more than one Bachelor’s or Master’s study right at the same Faculty. Therefore, when accepting an offered study place, the student will lose any previous BSc. or MSc. study right at the Faculty of Technology at the University of Turku.

Before you start preparing your application, always read the full admission requirements on the application portal Studyinfo.fi

The applicant’s previous degree based on which s/he is seeking admission to the Master’s Degree Programme in Mechanical Engineering must be in a relevant field of study. Relevant fields for the Digital Manufacturing specialisation track are

- Mechanical engineering

- Materials Science and Engineering

- Metallurgical Engineering

- Systems engineering

- Industrial engineering

- Production engineering

- Manufacturing

- Additive manufacturing

You may not apply to more than one specialization track within the same Master’s Degree Programme at the University of Turku. Therefore, you should carefully consider that your educational background is suitable enough for the track that you are applying to.

The decision of admission will be based on

- the relevance of the applicant’s awarded degree(s)

- the amount, relevance, and grades of the courses in the degree(s)

- the language test result (see Language requirements)

- the motivation letter and your answers to the optional questions included in the application

- possible relevant work experience

- possible interview

In addition to the education diploma and language certificate, you should include testimonials of any relevant work experience in your application.

The academic evaluation is made only for complete applications that are received during the application period. Any preliminary assessment of suitability or chances for admission will not be given.

Programme in brief

The Master’s Degree Programme in Mechanical Engineering: Digital Manufacturing is a two-year programme of 120 ECTS credits.

- Joint mechanical engineering studies 20 ECTS

- Digital Manufacturing studies 20 ECTS

- Thesis and project 40 ECTS

- Minor or Thematic Studies 20-25 ECTS

- Other studies 15-20 ECTS

Curriculum is published in the study guide.

The Digital Manufacturing track coordinated by “Digital Manufacturing and Surface Engineering (DMS)” research group at the Department of Mechanical and Materials Engineering is conducting cutting-edge research within the field of digital manufacturing. The DMS research group consists of over 25 experienced and young researchers (professors, scientist, engineers, PhDs, MSc and BSc students, interns/exchange students etc.) and is engaged with various national and international academic and industrial collaborators. The research conducted within DMS group as well as various other groups within the department around digital manufacturing covers topics such as:

- Additive manufacturing and surface coatings of smart materials (metals, ceramics, polymers and their composites) for various applications such as transport, biomedical, energy etc.

- Micro and miniaturized 3D-printing as well as large-scale 3D-printing

- Quality assurance of digital and traditional manufacturing process like welding, thermal spray by utilizing advanced in-situ and ex-situ sensorics and their use via artificial intelligence and machine learning in close collaboration with smart systems and computers sciences.

- Process monitoring of various processes and control along with artificial intelligence, modelling and simulation tools.

- Materials engineering in digital manufacturing such as microstructure engineering, solidification, advanced additive metallurgy, lab-scale and synchrotron-based characterization etc.

- Laser based processing (welding, cutting, cladding, printing, surface functionalization etc.)

Within the digital manufacturing track the students are given the flexibility to select the master’s thesis topics that are: (1) Part of the ongoing large national or international research projects within DMS or department, (2) Industrial case study where the student will be directly supported by the respective companies. Some examples of MSc thesis topics:

- Laser powder bed fusion additive manufacturing of novel steels

- Machine learning enabled smart additive manufacturing of metals

- Development of novel simulation and modelling tools for studying laser powder bed fusion

- Design optimization and printing of 3D industrial components

- How sustainable is additive manufacturing?

- Tribological and corrosion performance analysis of additively manufactured samples.

- Improved digital laser welding by utilizing advanced process monitoring

- Operando synchrotron characterization of additively manufactured specimens

Career prospects

After completing this programme the students shall:

- Have acquired a broader understanding of various traditional and state-of-the-art manufacturing technologies such as welding, machining, cladding, thermal and cold spray, etc. along with an in-depth understanding of the next-generation digital manufacturing technologies such as directed energy deposition, powder bed fusion, material jetting, etc. to utilize them for creating sustainable and digital industries;

- Be able to transform innovative ideas in the field of digital manufacturing into viable business solutions;

- Have gained a basic understanding of material science and engineering concepts relevant to digital manufacturing to succeed in developing novel materials for various digital manufacturing processes;

- Have attained a broader understanding of various surface and coating methods for modifying the surfaces of the digitally manufactured components for various industrial applications;

- Have acquired understanding of the processes, costs, working principles and quality assurance tools and procedure in modern industrial welding production.

- Be able to utilize advanced machine learning and artificial tools along with relevant modelling and simulation tools to improve the various additive manufacturing processes and resultant structures created by them.

- Be able to formulate research questions in the field of digital manufacturing, draw up plans accordingly and execute it during the thesis work by conducting scientific, ethical, and societally relevant research work as preparatory training for doctoral research studies in digital manufacturing.

After completing this programme the students shall acquire the following skills:

- In processing the raw material (powder, wire, liquid, etc.) using various heat sources such as laser, electron beam, arc, plasma, and light to create 3D printed components as well as 2D functional surfaces

- In analysing and developing new raw materials for 3D printing and related technologies

- In applying appropriate post-treatment (thermal and mechanical) methods to obtain finished 3D printed components

- In characterizing raw materials, 2D functional surface coatings and 3D printed parts using basic and advanced material characterization techniques

- In using some of the fundamental tools in modelling, simulation and machine learning

After completing this programme the students shall gain the competence in following areas:

- Materials processing via 2D and 3D printing technologies which uses various heat sources such as laser, electron beam, arc, plasma, light

- Tools to analyze and develop new raw materials for 3D printing and related technologies

- Tools to post treat (thermally and mechanically) the 3D printed parts

- Basic and advanced material characterization techniques to study raw materials and 3D printed parts

- Fundamental tools for modeling and stimulation used in additive manufacturing

The employment percentage of those holding an M.Sc.(Tech.) degree is high in Finland. Moreover, since digital manufacturing has become extremely popular among various industries in Finland as well as globally this specialization track offers several career opportunities in both industrial as well as other jobs.

Industries around the globe are thriving for maturing various digital manufacturing technologies and are facing a serious deficiency of skilled engineers trained in such a highly demanding field. Therefore, after completing this program the students are well trained to solve real challenges in various industrial sectors including but not limited to aerospace, space, automotive, bio-medical, marine, nuclear, power and energy etc.

After successfully finishing this program the student can go to industries as well trained

- Additive Manufacturing process specialist,

- Design specialist,

- Materials specialist,

- Characterization specialist,

- Surface engineering specialist

- Modelling and simulation specialist

- Specialty in machine learning within digital manufacturing

After successfully finishing this programme the student can also opt for a research career by enrolling in a Ph.D. program with specialization in 3D printing, process monitoring, materials processing using laser and plasma, flame, thin and thick coatings, tribology, biomaterials, etc.

Graduates from the programme are eligible to apply for a position at the University of Turku Graduate School, UTUGS. The Graduate School consists of doctoral programmes, which cover all disciplines and doctoral candidates of the University.