Doctoral dissertation: Safer batteries for small devices – thermal spray techniques open new possibilities for manufacturing solid-state batteries

Thin-film all-solid-state batteries are particularly well suited as power sources for small electronic devices. Compared to conventional lithium-ion batteries, they offer improved durability and safety. However, challenges related to manufacturing have so far limited their wider adoption. In M.Sc. Arman Hasani’s doctoral research, thermal spray and laser post-processing techniques were investigated as potential manufacturing routes for these next-generation batteries.

An increasing number of everyday devices rely on rechargeable batteries. They power our phones, laptops, medical devices, and electric vehicles. As the world moves toward cleaner energy and safer technology, there is a growing need for batteries that last longer, work more reliably, and pose fewer safety risks.

This dissertation focuses on a new class of thin-film all-solid-state batteries. Unlike traditional lithium-ion batteries, these batteries do not contain flammable liquid electrolytes. Instead, they are based entirely on solid materials, making them significantly safer, as they cannot leak or catch fire in the same way as batteries with liquid electrolytes.

The thin-film solid-state batteries studied in this work are especially promising for small-scale and emerging technologies.

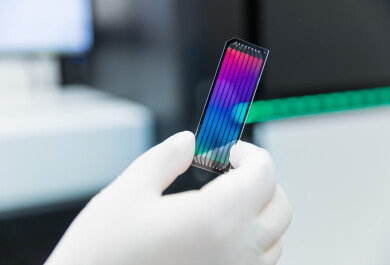

“Thin-film solid-state batteries can be manufactured to thicknesses of just a fraction of a millimeter and are currently best suited for very small devices, such as sensors, medical implants, other microelectronic and EVs. However, their safety, durability, and the growing use of small electronics make them an important battery technology to develop,” says doctoral researcher Arman Hasani.

Despite their advantages, these batteries are still difficult and expensive to manufacture. Current production methods are slow, limited to relatively small areas, and require several separate processing steps. This makes scaling up production challenging and costly, especially if one wants to coat larger or more complex components. A major challenge therefore is finding faster and more practical ways to make the thin ceramic layers that form the key parts of the battery.

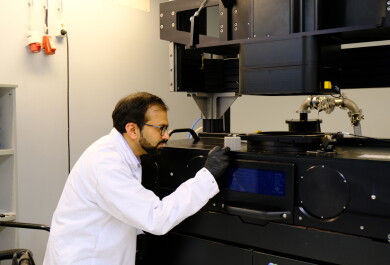

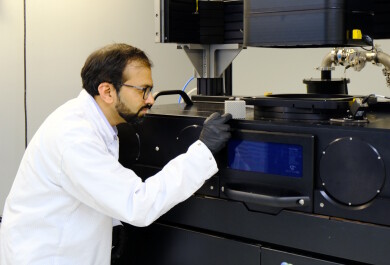

The main goal of this research was to explore new manufacturing routes using thermal spray techniques and laser post-processing, which are already widely used in industry for coating large surfaces quickly and efficiently for various other applications than battery.

In the study, thermal spray techniques were applied to two critical battery components: the anode, which stores lithium during charging, and the solid electrolyte, which allows lithium ions to move safely inside the battery.

The results show that different thermal spray methods have a significant impact on material quality. Some techniques preserved the battery materials well, while others caused damage, especially through the loss of lithium. These differences strongly affected the functional performance of the battery layers.

In addition, the research also showed that a short laser post-processing after spraying can greatly improve the quality of the layers. This laser post-processing made the coatings denser, smoother, and more uniform without overheating the entire battery.

Advanced measurement tools available at synchrotron research facilities were also used in the study. These tools made it possible to look inside the battery layers in great detail and reveal changes that cannot be seen with standard laboratory equipment. This allowed the research to clearly link manufacturing methods to material quality and battery performance.

Overall, this work provides new insights into how solid-state battery materials behave during fast industrial manufacturing processes. It shows that thermal spray techniques and laser post-processing can be used to form functional battery layers and highlights both their potential and their current limitations.

“The study identifies which processes work best and where material damage can occur, offering practical guidance for future battery development. It also shows that thermal spray techniques and laser post-processing could serve as the viable manufacturing routes for thin-film solid-state batteries, supporting the development of safer and more scalable battery technologies,” Hasani concludes.

Dissertation defence on Friday 20 February

M.Sc. Arman Hasani defends the dissertation in Mechanical Engineering titled “Advanced Characterization of Thermally Sprayed Thin-Film All-Solid-State Batteries” at the University of Turku on 20 February 2026 at 12.00 (University of Turku, Publicum, Pub3, Assistentinkatu 7, Turku).

Opponent: Associate Professor Heli Koivuluoto (Tampere University, Finland)

Custos: Associate Professor Ashish Ganvir (University of Turku)