Over €5 million for University of Turku-led project aiming to revolutionise plasma generator technology with multi-material additive manufacturing

A new international consortium project led by the University of Turku has received the EUREKA label and funding, with a total budget of €5.5 million. The project will pioneer breakthroughs in plasma generator technology for extreme-heat applications through multi-material laser powder bed fusion additive manufacturing.

The University of Turku will coordinate a groundbreaking international research and innovation initiative, Laser powder-bed-fusion Additive-Manufacturing of complex multi-material Refractory-Copper Plasma generation devices (AM4Plasma). The aim of the project is to enable next-generation plasma generator hardware using multi-material metal 3D printing. The breakthrough technology will enable radically improved performance in plasma spray systems, as well as future fusion-energy and aerospace propulsion platforms.

Funded under the EUREKA Network, the project brings together leading partners from Finland, Canada, Austria, Belgium, Poland, and Sweden, and will run from 1 February 2026 to 31 January 2029. The University of Turku’s share is €1.5 million, supported in Finland by Business Finland’s Co-Innovation programme.

New technology to enable next generation plasma spray technology, nuclear fusion, and propulsion systems

AM4Plasma aims to fundamentally transform plasma generator manufacturing by leveraging multi-material metal 3D printing, enabling operating conditions far beyond current industrial capability. Plasma generators produce extremely high-temperature plasma and are central to advanced plasma spray coating systems. This project will enable the next generation of plasma generator hardware not only for future plasma spray technologies but also for extreme-temperature applications such as fusion reactors and aerospace propulsion systems.

Plasma generator components in high power plasma spray technology must withstand heat fluxes exceeding 17 MW/m², similar to those found in nuclear fusion reactor walls. These parts combine high-thermal-conductivity copper with ultra-high-temperature refractory metals such as tungsten, molybdenum, tantalum, and niobium.

Conventional manufacturing cannot reliably combine such metals or their novel alloys and produce advanced architectures like conformal cooling channels as well as functionally graded interfaces.

“This project is about pushing the boundaries of metal additive manufacturing to its extreme,” says Associate Professor Ashish Ganvir, coordinator of AM4Plasma at the University of Turku.

“By combining multi-material metal 3D-printing, new alloy design, process intelligence, and advanced simulation, we aim to enable plasma generator hardware with radically improved efficiency, lifetime, and functionality and open pathways toward next-generation plasma spray, fusion and propulsion systems.”

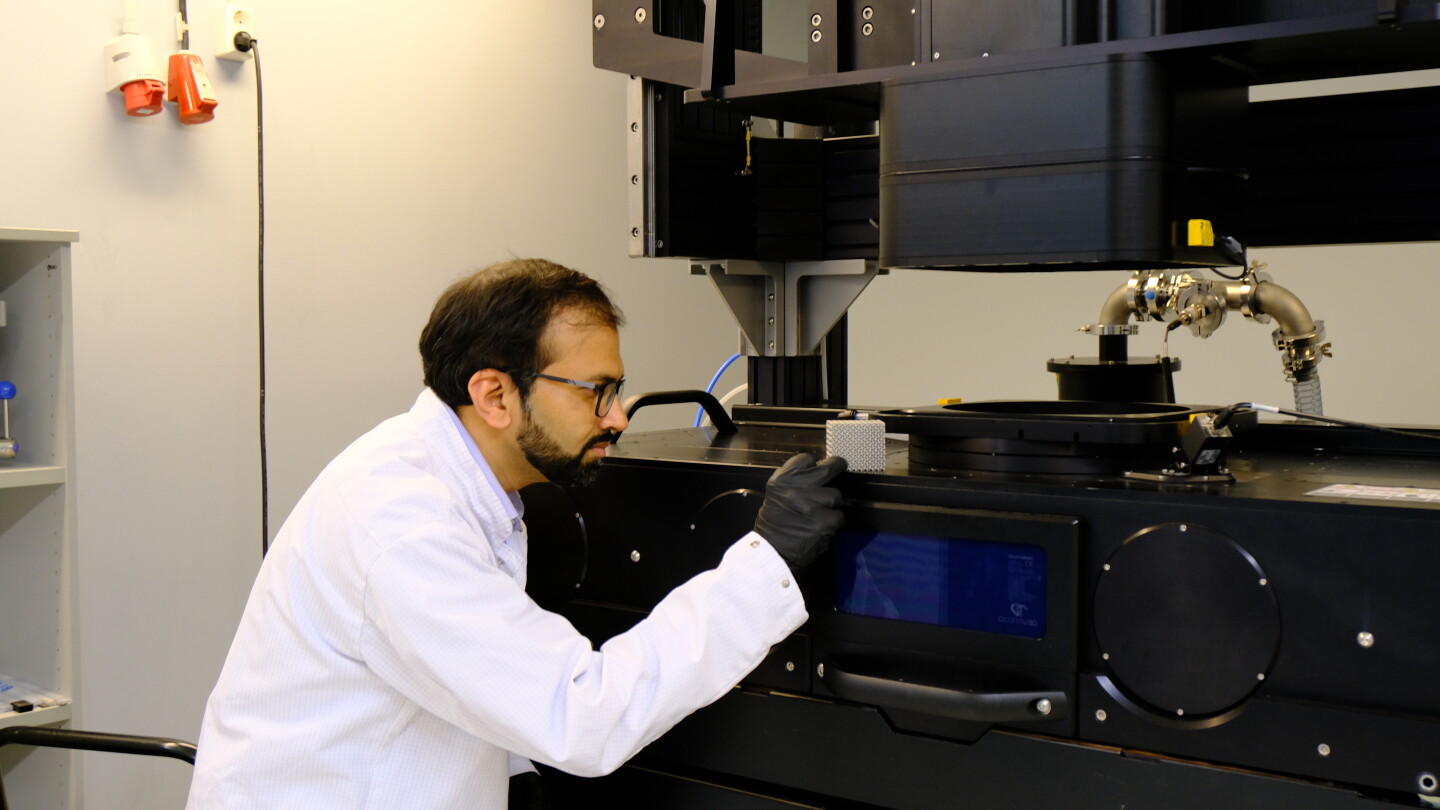

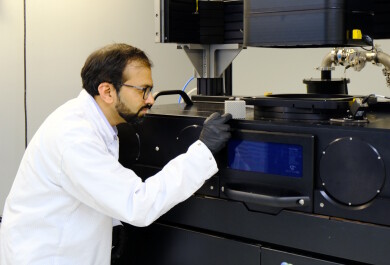

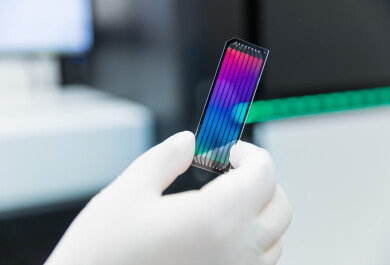

A dual-metal 3D-printed University of Turku logo manufactured by Doctoral Researcher Ammar Anjum (DMS Group) using the AconityMIDI+ laser powder bed fusion system. The print combines copper and nickel alloys, demonstrating the multi-material additive manufacturing capability central to the AM4Plasma project.

AM4Plasma will integrate real-time diagnostics, operando characterisation, and multi-scale simulation to study solidification, phase evolution, bonding mechanisms, and interface formation during printing.

“At the heart of AM4Plasma lies the challenge of integrating copper’s exceptional thermal conductivity with the strength and temperature resistance of refractory alloys, one of the toughest frontiers in metal additive manufacturing,” Ganvir adds.

University of Turku leads a world-class consortium

The University of Turku will coordinate the project and lead the development of multi-material laser powder-bed fusion (PBF-LB) technology, including multi-material printing, alloy design, process monitoring, and computational metallurgy. The funding will support new doctoral and postdoctoral recruitment and strengthen multi-material additive manufacturing infrastructure in Turku.

The consortium spans the entire value chain, from powder development and AM technology to post-processing, advanced characterisation, and industrial validation, ensuring rapid translation to industrial use.

In Finland, the project partners are VTT Technical Research Centre of Finland, Electro Optical Systems Finland Oy, Top Analytica Oy and Delva Oy. The international partners in the consortium are Metalpine GmbH and Thermal Spray Innovations GmbH (Austria), Schaeffler Aerosint SA (Belgium), Northwest Mettech Corp. (Canada), AMAZEMET Sp. z o. o. (Poland), as well as Quintus Technologies AB and Thermo-Calc Software AB (Sweden).

AM4Plasma will train future experts in multi-material additive manufacturing, alloy development, computational metallurgy and advanced lab-scale and large-scale material characterisation.

“Training new experts will strengthen Finland’s and Europe’s competitiveness in advanced multi-material additive manufacturing technologies,” says Ganvir. “AM4Plasma demonstrates how deep metallurgical science combined with industrial-scale additive manufacturing technology can transform critical sectors, from thermal spray and fusion to propulsion systems.”

In Finland, the project is funded by Business Finland through the Co-Innovation funding model. In Poland, funding comes through the NCBR (National Centre for Research and Development). In Austria, funding is provided by FFG (Austrian Research Promotion Agency). Other countries are participating as in-kind partners.